Custom Metal Stamping Die Manufacturing

Whether you’re creating a 3,000 lb. assembly with tight tolerances or producing parts for a mission-critical application, tooling matters. Building metal stamping dies is a very manual, skill-driven process – one that’s critical to your project’s success.

From detailed schematics to runoff testing, MAINWAY hosts complete services for building new dies. Using our state-of-the-art CNC equipment, you can achieve production-ready results – at any volume – for a variety of applications.

How We Work – Metal Stamping Dies

The outcome of a die stamping project is highly dependent on the original tool maker. That’s why we’ve spent nearly 45 years refining our expertise in a wide variety of dies:

- Progressive dies

- Transfer stamping dies

- Hand transfer dies

- Draw dies

- Deep draw dies

- Line dies

- Compound blank

- Fine blanking

We also offer custom machine builds. And as a full-service stamping die manufacturer, we can guide and support your project in many other ways:

- Die design & prototyping

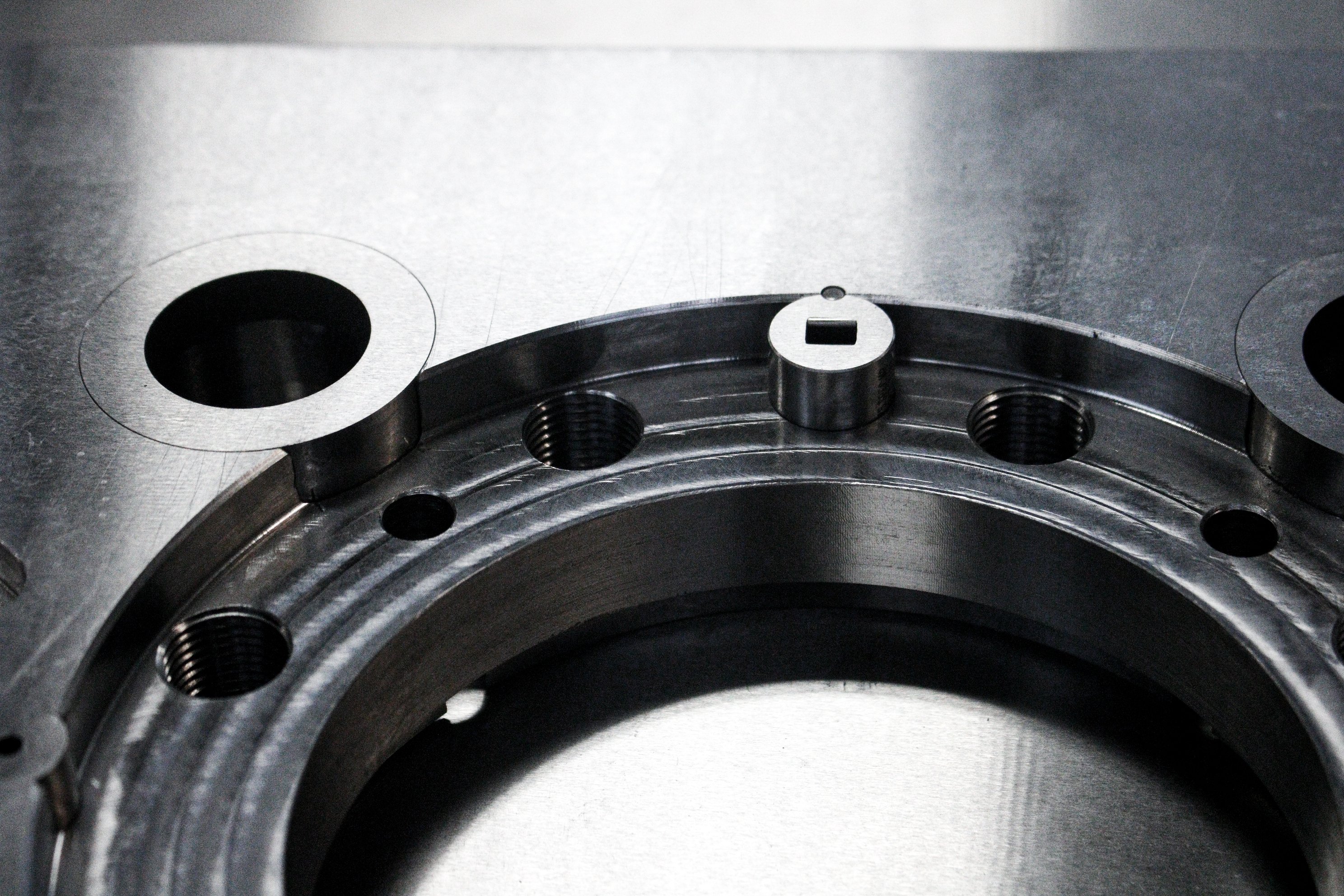

- Die fabrication

- Production stamping

- Value-added services – i.e. welding, fixtures, sub-assembly

- Die repair

You + MAINWAY

To ensure both sides understand the project’s requirements and opportunities, we review the die’s design and the needs of the part you’ll ultimately produce. We talk to you designer-to-designer, establishing how your fabricated die parts will come together successfully.

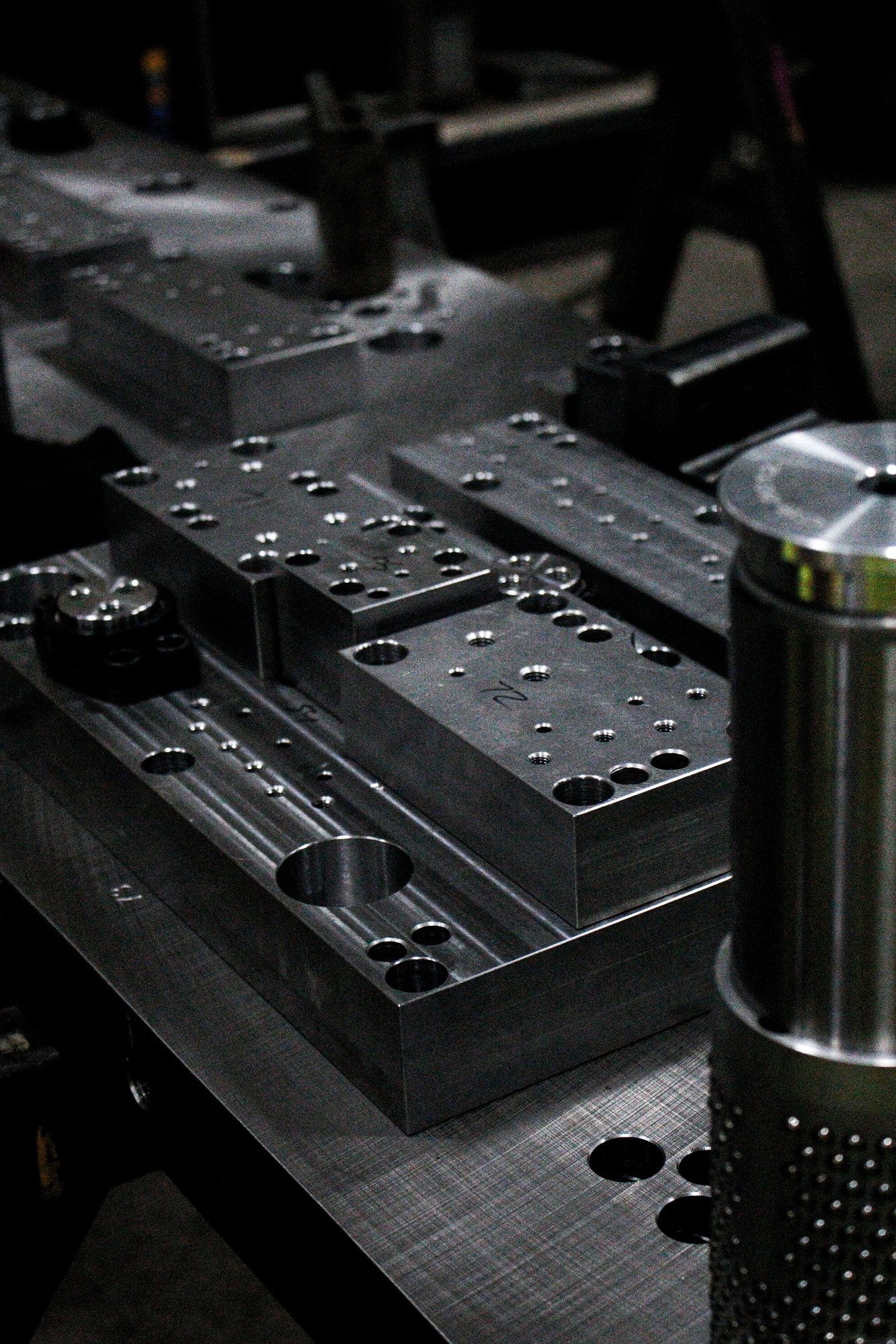

We take your die fabrications and build the tooling! Our state-of-the-art CNC, waterjet and/or wire EDM machines do their thing.

The custom die won’t get our final OK until it’s passed quality and dimension checks and has run off ~100 parts on the press. Some clients visit on-site at this stage to see the amazing results in person.

Our Precision Die Specs

Metals

We build metal stamping dies with material to suit your application. We work with various grades of steel, stainless steel, aluminum and copper. We understand exactly how your end product’s high-performance and exotic materials will hold up against our tooling.

Bed Sizes

MAINWAY’s largest bed is 72” front-back and 132” left-right. Our largest bed with a feedline is 60” front-back and 96” left-right. Other key specs:

- Press capacity: 40-800 tons

- Space: 50,000+ sq. ft. across our facilities

In-House Skill

The design and fabrication of components for your die build all happens under one roof at MAINWAY, strategically located near major North American highways. We also offer wire EDM, waterjet, and other in-house capabilities, ensuring your project comes to life correctly and quickly.